Choose a category

극한 환경에서 작동

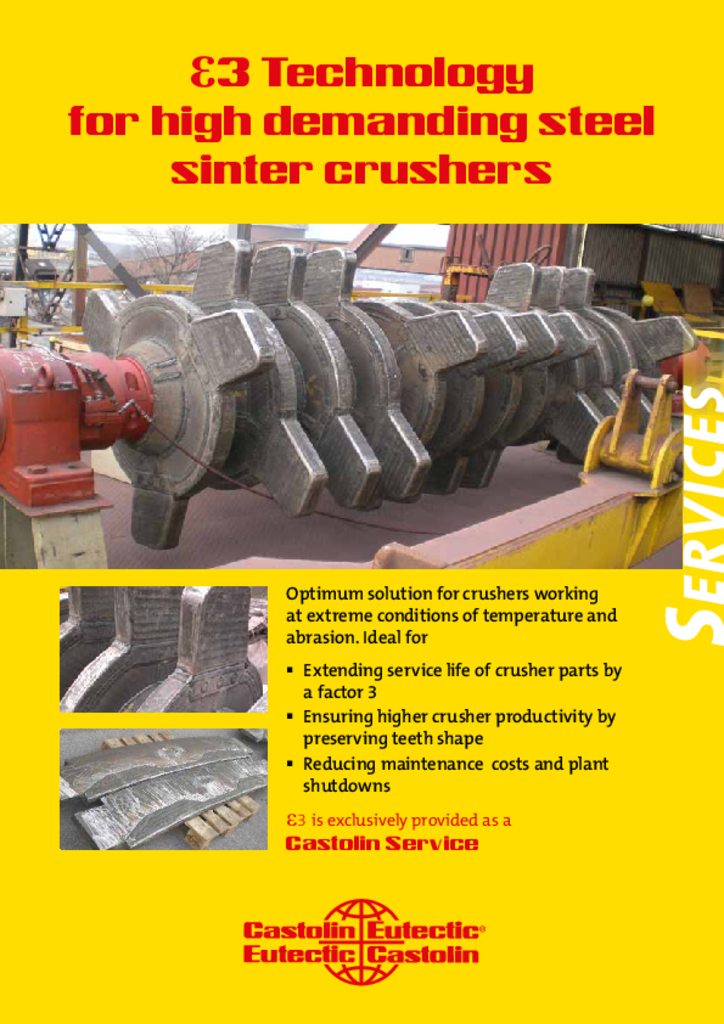

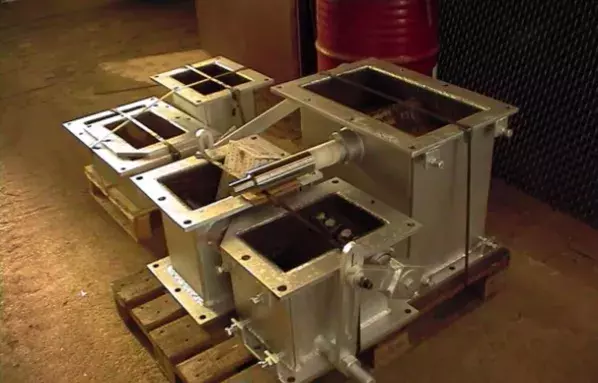

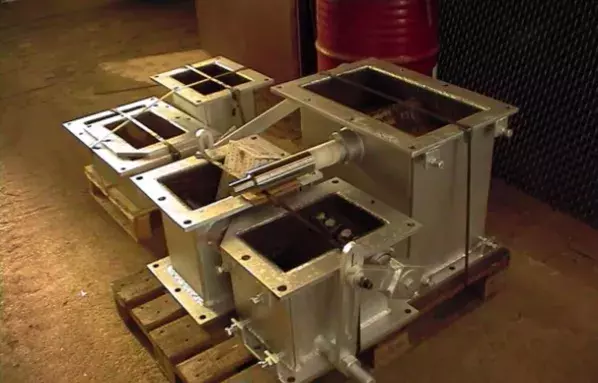

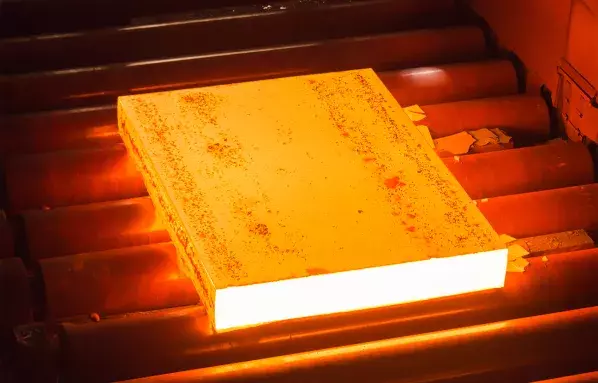

철강 공장에서 초고온에서 소결을 처리하는 장비는 심각한 마모 조건에 노출됩니다. 특히, 대량의 처리량을 보장해야 하는 소결 파쇄기는 값비싼 유지 보수 및 빈번한 공장 가동 중지를 피하기 위해 내마모성을 갖추어야 합니다. 유지 보수 관리자들은 시장에서 구할 수 있는 표준 솔루션으로는 필요사항을 충분히 충족할 수 없다는 데 동의합니다. 로터 및 브레이커 바는 정기적으로 새것으로 교체되어야 합니다.

표준 솔루션의 내마모성이 충분하지 않은 이유는 다음과 같은 세 가지 주요 요인 때문입니다.

• 경화 특성을 감소시키는 고온 소결

• 부품들을 마모시키는 소결 연마 재질

• 하드페이싱을 쉽게 파괴하는 강한 충격

e3가 표준 솔루션보다 3배 이상 우수한 것으로 나타났습니다

e3는 철강 공장의 소결 파쇄기의 생산성과 수명을 향상시키기 위해 특별히 개발되어 법적인 보호를 받는(특허를 받은) 솔루션입니다. 이 솔루션은 실제 작업 조건뿐만 아니라 실험실에서 4년간의 테스트를 거쳐 탄생했습니다. 충격과 마모가 있을 때에도 탁월한 내성을 제공하는 유니크한 Castolin Eutectic 고온 내마모성 합금에 기반합니다. e3는 로터 디스크, 톱니 및 브레이커 바와 같은 소결 파쇄기의 주요 부품을 보호하는데 특히 적합합니다. 현장 테스트 결과 e3가 표준 솔루션보다 3배 이상 우수한 것으로 나타났습니다. 수명을 늘리는 것 외에도 부품의 기하학적 모양이 유지되어 표준 솔루션에 비해 분쇄기 효율성이 향상됩니다.

당사 엔지니어는 귀하의 요구에 맞는 특정 솔루션을 설계할 수 있습니다.

부품 수명을 늘리는 것 외에도, e3은 다음을 가능케 합니다.

• 소결 파쇄기 유지 보수 및 공장 가동 중지 빈도 감소

• 톱니 모양을 보존으로 높은 분쇄기 생산성

• 새로운 부품의 구매 비용 절감

• 복잡한 수냉식 브레이커 바 사용을 피함

MADE BY LASER CLADDING

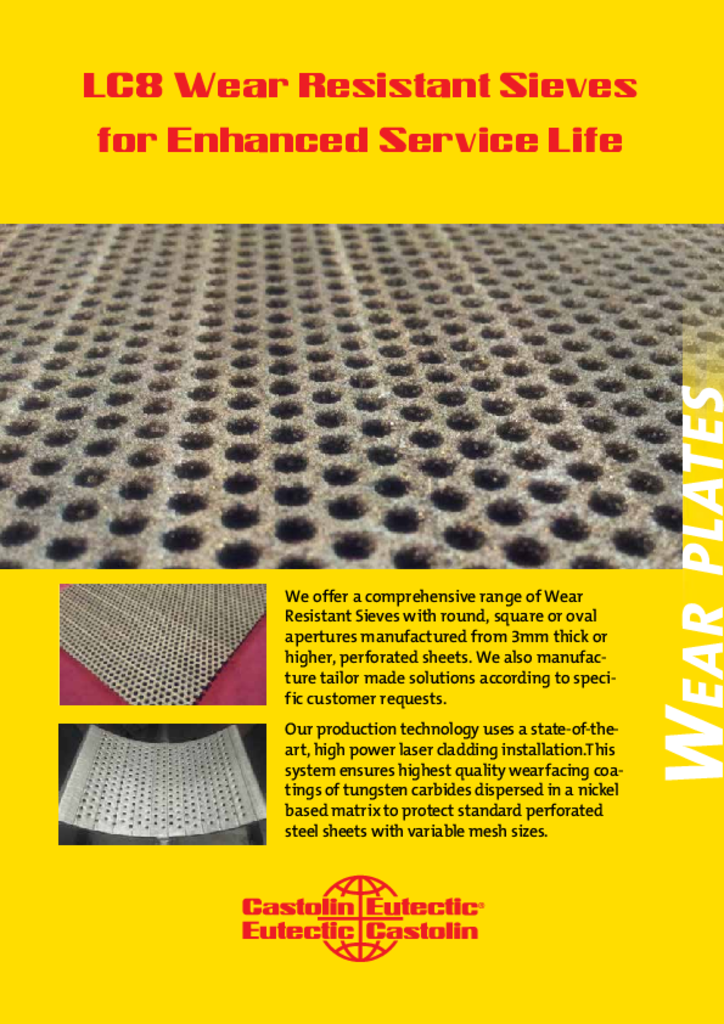

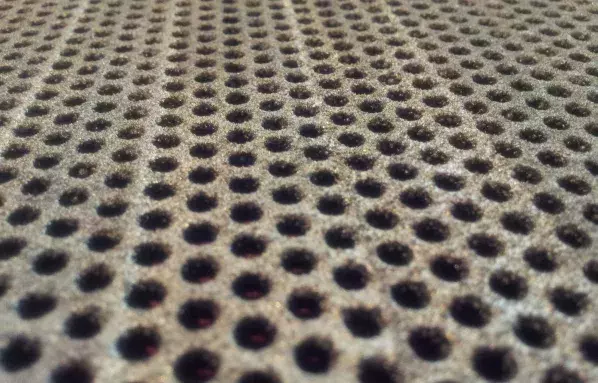

We offer a comprehensive range of wear-resistant sieves with round, square or oval apertures manufactured from 3 mm thick or higher, perforated sheets. We also manufacture tailor-made solutions according to specific customer requests. Our production technology uses a state-of-the-art, high power laser cladding installation. This system ensures highest quality wearfacing coatings of tungsten carbides dispersed in a nickel-based matrix to protect standard perforated steel sheets with variable mesh sizes.

Much better than standard steel

The ultra hard tungsten carbide phases which are homogeneously distributed within a self-fluxing, tough nickel-based alloy matrix, provide:

- Extreme wear resistance performance against abrasion and erosion up to 10 times higher than standard, monolithic heat-treated steel alternatives.

- Withstands operating service temperatures up to 400°C. For even higher service temperature requirements, a diverse range of special alloy systems may be proposed to meet specific customer needs.

Modern Castolin Eutectic LaserClad technology uses a focused laser beam to ensure low heat input welding conditions, which translates into extremely effective, wear protective coatings on industrial parts.

Other Solutions for Sinter Plants

After mixing the raw materials in the sinter plants (fine iron ores, additives such as limestone and olivine, recycled iron-bearing materials from downstream operations, and coke breeze) we find a roller just underneath the charging system to constantly feed the sinter belt which is affected by abrasion. The lifetime of this feeding roller can be increased by our turnkey solutions.

Increase lifetime with CDP® wearplates

In most cases after the sinter discharge, crushing and hot screening, the sintered material proceeds to a separate cooler. This is typically a rotating structure, divided into circular sectors with tipping devices, in which the sinter is placed in a layer more than 1 m thick and cooled by fresh air.

When the sinter has completed the cooling cycle, each sector is emptied via the tipping device. The cooled sinter is transferred to screens that separate the pieces to be used in the blast furnace.

Both the charge and discharge of the cooler deteriorate the surfaces whose lifetime can be increased with our CDP® wearplates.

Cooling the steel is a critical factor

Along the whole sinter process, several metallurgical and chemical reactions take place which produce dust and gaseous emissions apart from the sinter itself. These gases contain particles such as heavy metals that will weaken the inner surface of air suction systems.

A complete high resistance conduction system including valves and transitions circular to square section can be manufactured with our CDP® wearplates.

Monitor Coatings의 CastCoat

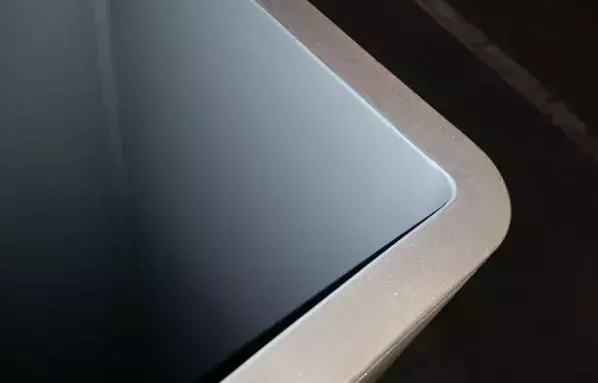

CastCoat 경질 복합 코팅은 영국의 Castolin Eutectic 자회사 Monitor Coatings가 20년 이상 연속 캐스터 구리 금형 플레이트 코팅을 위한 철강 산업 응용 분야를 위해 개발되었습니다. 테스트 결과 코팅이 다른 구리 금형 플레이트 코팅보다 강하다는 것이 밝혀졌습니다. 마찰 계수가 낮아 스티커 알람 감소에 도움이 되며 코팅이 액체 강 및 주조 파우더에 비활성 상태가 됩니다. 코팅 시스템은 금형 레벨 감지기 또는 전자석 교반기에 영향을 끼치지 않습니다. 또한 코팅이 열전달율에 무시할 정도의 적은 영향을 미치는 것으로 입증되었습니다.

현재 성숙한 기술

코팅 뒤에 수년간의 현장 데이터를 통해, 제품 모양 개선과 함께 두꺼운 슬래브 캐스터의 경우 3-4배, 얇은 슬래브 캐스터 좁은 플레이트의 경우 최대 6배와 같이, 상당한 동판의 수명 개선이 입증되었습니다. 작동 중, 코팅은 내마모성의 급격한 증가를 통해 연장된 주조 작업을 가능하게 하는 것으로 나타났습니다. 높은 응력 위치에서의 열 피로로 인해 코팅의 점진적 분해가 발생합니다. 이제 전 세계 고객 기반을 갖춘 성숙한 기술인 CastCoat는 사용자에게 비용/톤을 절감을 계속 제공합니다.

새로운 소형 HVOF 장치

금형의 4면을 모두 코팅함으로써, 캠페인 내내 치수 안정성이 유지되어 제품 모양과 쉘이 지속적이고 효과적으로 성장하게 됩니다. 눈에 띄는 마모가 없다는 것은 금형 교환 사이에 더 긴 캠페인이 가능하여 더 높은 캐스터 가용성을 달성한다는 것을 의미합니다. 추가로, 코팅에 의해 제공되는 보호 기능은 동판 수명을 연장시켜 연간 구리 비용을 절감하고 온라인 및 오프라인 유지 보수 비용을 크게 절감합니다. 최근 소형 HVOF 장치가 개발됨에 따라 이제 CastCoat 복합 코팅을 튜브 금형에 적용할 수 있습니다.

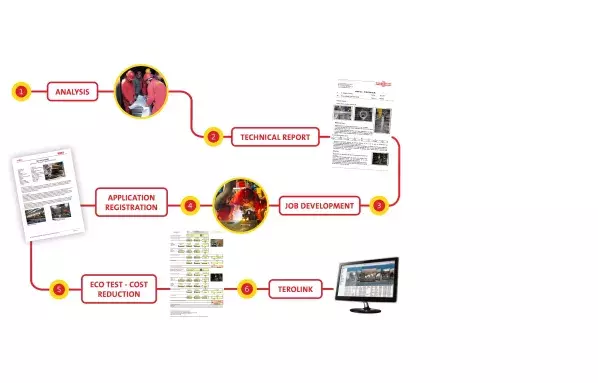

Our working method for cost savings

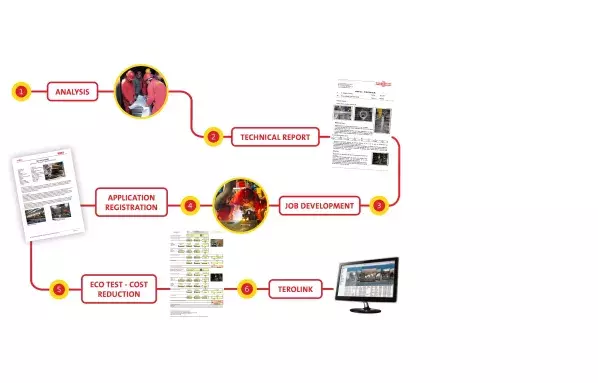

Since a very long time we are successfully applying a partnership program, focused on cost reductions. This smart Maintenance and Repair program can be summarized in six steps:

- Analysis: The first step to a good solution is a correct analysis.

- Technical Report: With the information provided, our Technical Department prepares a report.

- Job development: Once the client considers the repair to be feasible, Castolin Eutectic puts at your service all the Technical Department for the development of the procedure outlined above.

- App registration: Always subject to the customer’s approval, we first propose to register the job done in our confidential “FAR” database where the short application summary remains on hold until confirmation of service results.

- EcoTest: At the end of the service life of the part involved, we are ready to establish a detailed cost analysis to evaluate the practical direct savings achieved through mutual collaboration.

- Terolink: Finally we propose to submit the complete application as verified in our Terolink Database.

RAW MATERIAL PROCESSING & HANDLING

Iron ore, coal, limestone, fluxes and scrap are unloaded in the raw material area. They are classified, stored, crushed, grinded and handled for transport into the next production process. All these activities produce a combination of wear phenomena in the different machines and parts involved. Their service lifetime can be extended with different solutions, thanks to the cost reduction program from Castolin Eutectic.

The first step for a good solution is a correct analysis

After processing the respective raw materials, they pass through the blast furnace, electric arc furnace (EAF) or basic oxygen furnace (BOF) to get pig iron or Steel. The first step for a good solution is a correct analysis. To facilitate this, we have created an analysis document that can easily be completed in collaboration with our technical delegate. The document reflects the most important parameters to be considered to develop in-house solutions to your wear problems.

Repair Continous Casting Rollers according to OEM specifications

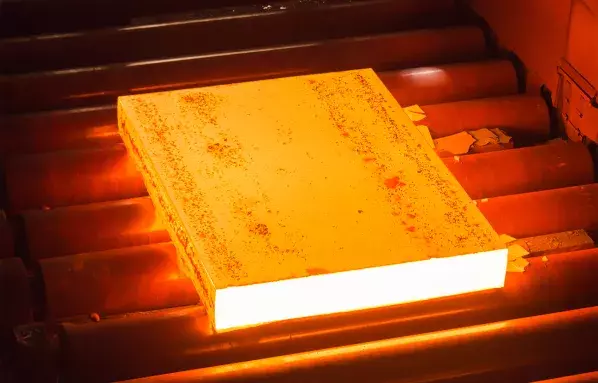

Continuous casting rolls are critical parts that are used for making the slabs, blooms or billets just after the tundish and moulds, at a very high temperature. The extreme working loads as well as the high temperature wear-out the rolls surface and, as a result, parts are damaged. Maintenance managers regularly have to decide to either scrap these expensive parts or try to repair them according to OEM specifications.

Rebuilding and repairing rolls for steel processing facilities

The semifinished products obtained after the continuous casting process have to be shaped before being comercialized. The first of these processes is hot rolling, from which sometimes final products are obtained and other times semifinished products intended for cold rolling or coating.

cooling the steel is a critical factor

In all rolling processes, cooling the steel is a critical factor. The speed at which the rolled product is cooled will affect the mechanical properties of the steel. Cooling speed is controlled normally by spraying water on the steel as it passes through and/or leaves the mill, although occasionally the rolled steel is air-cooled using large fans.

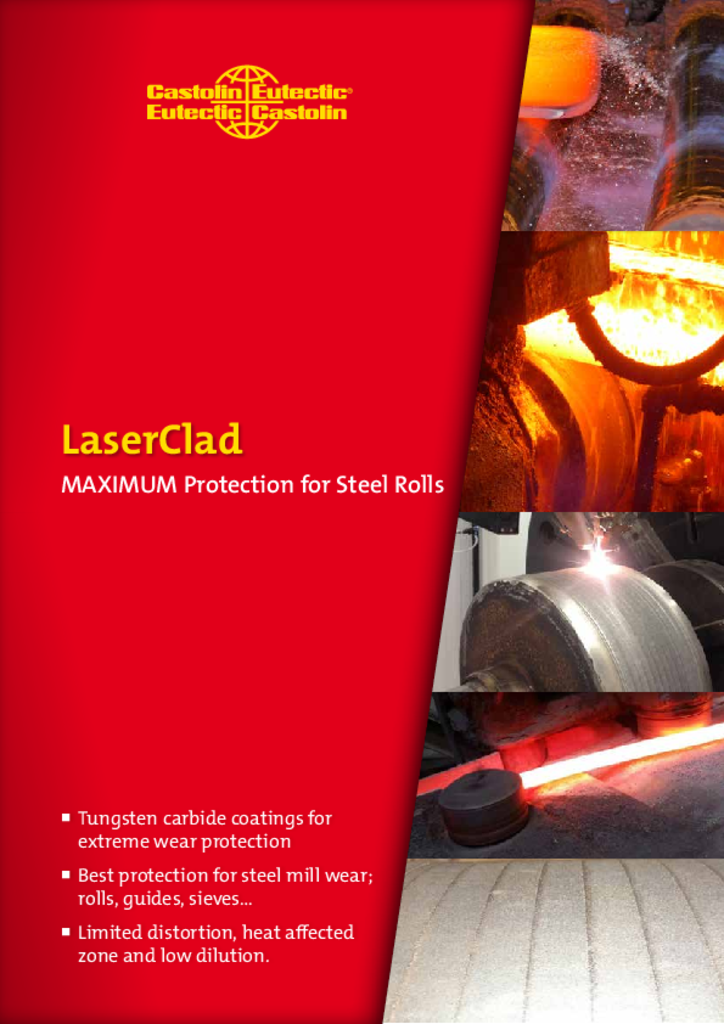

Rolls protected by laser cladding

Since the installation of laser cladding technology in the Castolin Eutectic Services Centers the wear protection of key tools such as rolls and guides has been raised to a new level. The utilization of 8kW High Power Direct Diode (HPDD) with automation leads to flexible production and superior quality. In addition, the powerful laser enables high deposition rates that can reduce the cost of the cladding operation. Compared to standard welding techniques, the dissolution of the carbides and the dilution of the cladding material are the lowest that can be achieved. As a result, the wear-resistance is maximized and the service-life is longer. The unique broad beam (up to 23mm wide) produces a flat coated surface that minimizes subsequent machining or grinding. Rolls can often be used as welded without further processing. The low heat input of the laser process means the lowest distortion of large and thin wall parts that can easily be cladded.

Rolls protected by spray & fuse

OEMs usually provide parts that have the surface coated with high wear resistant alloys such as Eutalloy® RW 12496. This coating is applied first by spraying a powder on the roller surface and then by fusing it just above the liquidus temperature. The process allows the coating to offer its best wear resistant properties and to perfectly bound on the steel substrate. On long and heavy parts, fusion is extremely difficult to be done correctly. Just after the spraying step, the part must be pre-heated homogeneously and kept in temperature while several torches fuse the powder all along the roll. In 2m long massive rolls, fusion may require up to 7 hours and any variation in temperature may result on an irregular surface quality. Since the part is exposed to very high temperature, deformation is also critical, especially on rolls made with thin wall tubes. Finally, if cooling is not well managed, thermal stresses can be so high that cracks may appear on the overlay. Our well-equipped service workshops as well as more than 10-years experience allow us to offer high quality overlays. Parts are coated by highly skilled operators that follow strict manufacturing methods. They regularly apply several powders according to what has been defined by OEMs.

다른 산업 발견