Choose a category

利用p宝发旋转工具的切割工艺

钻井工具作用于不同硬度,质地和尺寸的研磨材料,例如花岗石,石英,玄武岩,砾石等。如果遇不易劈开的紧密地层冲击碎片,或钻井,及旋转稀松易劈开材料运输,发动机的主要功能随之变化。

这些冲击工具 (杆) 一般能承受重大撞击 和磨损。因此,合金材料一般选择倾向于抗压缩的 冷加工沉淀。

针对塞块和磨损的合金保护

每个工具均是特定的,其工作状态取决于土壤的性质。虽然如此,每个工具均适用两者应用情形:

如工具遭受些许撞击,用 铁铬合金进行磨损防护。

通常情形下,这些工具 要受到 有损防护金刚结的撞击。因此,应选择耐撞击的钨钢 合金。

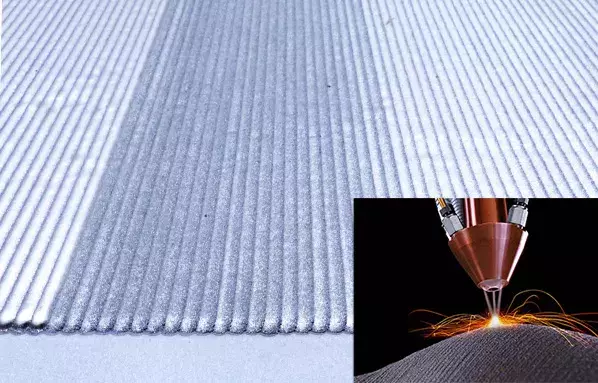

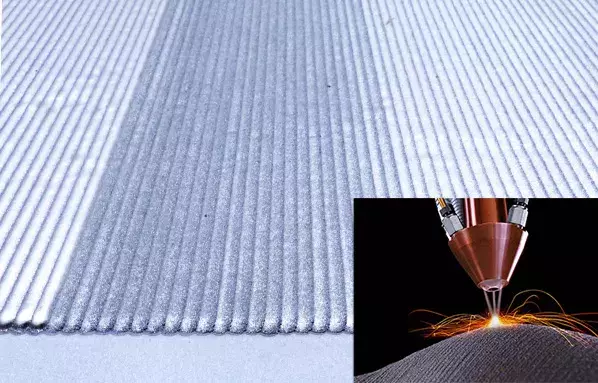

CUTTING-EDGE LASER CLAD WEAR LINERS

Avoid equipment failures and drastically reduce downtime with the most lightweight wear protection available with superior surface hardness. CDP LaserMax is the optimal choice for protecting mining parts exposed to high wear with minimum component stress, including mine ventilation fans, mine skips, conveying systems, and certain material handling systems.

Our laser clad wear plate is metallurgically bonded with wear-resistant proprietary alloys in an ultra-thin design. The powder becomes the sacrificial layer on the base plate, offering maximum protection at minimum weight.

- Superior surface hardness

-

Ease of handling and installation

-

Improved mine safety and work environment

-

Light-weight alternative with reduced energy consumption

-

Increased sustainability

ENHANCE OVERALL WEAR LIFE WITH CASTOCHROME CASTINGS

Fixed Plant

-

Mill feed & discharge chutes

-

Transfer & load-out chutes

-

Skip discharge chutes

-

Surge bins and receiving hoppers

-

Conveyor skirt liners

-

Vibratory and grizzly feeders

-

Apron & pan feeders

Mobile Plant:

-

Dragline buckets

-

Electric rope shovels

-

Wheel loader buckets

-

Dozer blades

-

Truck boxes

避免设备故障

运输高度需变化或长距离运输时, 拖链式输送机 非常适合运输木材,煤炭,石灰或废料等物料。但不幸的是,运输物料产生的

- 摩擦磨损运输机的表面,

- 增加拉倒链条的力度,从而 对设备的使用寿命产生负面影响。

大部分时间, 链条路径会出现高强度摩擦。结果是,表面不再光滑,力度增加,链条受损,零件必须定期更换以避免设备故障

比传统 硬质钢耐磨4倍多

多年来,Castolin Eutectic 以其知名的 CDP®耐磨板保护客户的运输机表面。优质抛光CDP®耐磨板 也可安装在要求低摩擦的表面上。今天,基于类似的理念,我们提供易安装的WSS,保护链条路径,免于严重的磨损和摩擦。WSS是一种复合材料,用低碳钢和具有高度抗磨性合金制成,摩擦系数低。 为确保良好的滑动特性,减少链条运输机能源消耗,条状表面进行了抛光处理。 因此,我们的抗磨条比传统的硬化钢至少耐磨4倍。表面可长期保持光滑,从而最终减少链条损坏。WSS也适用于在磨损环境中需承受高强度和高振动的机器。

BENCHMARK BACKFILL SLURRY WEAR PERFORMANCE

Where safety meets efficiency and productivity

-

Benchmark performance | Reduced cost per tonne ownership

-

Engineered pipe connections | Efficient retrofit and new installations

-

Process controlled cladding ensures superior performance

-

Technical support | Site-specific wear surveys and performance monitoring

-

Mine contractor grade offerings | Ease of installation & impact resistant formula

ECONOMICAL WEAR RESISTANT PIPES FOR SLURRY BACKFILL TRANSPORTATION

MeCaPipe is our economical alternative to CastoTube wear pipes. MeCaPipe incorporates the high-performing MeCaTeC lining technology to offer an alternative solution for general slurry applications. Combined with CastoTube, MeCaPipe can meet specific client requirements to provide the adequate level of protection against abrasion, erosion and corrosion. For a seamless wear performance, the lining thickness is typically selected based on the finished ID to match the existing piping system.

MeCaPipe is engineered to withstand slurry wear and erosion. It outlasts traditional piping materials, minimizing costly changeouts and providing enhanced performance and operational efficiency. MeCaPipe can be easily repaired or relined to prolong life.

Our team will work closely with your mine to deliver the right pipe lining solution to optimize your slurry backfill transportation systems.

Contact us for an expert wear pipe analysis.

MINE-GRADE WEAR COMPOUNDS FOR ABRASION, EROSION AND CORROSION PROTECTION

From repair and rebuild to corrosion resistant barrier coatings, MeCaTeC offers an industry-leading range of engineered polymers that will perform in the most demanding mining applications. MeCaTeC is the ideal solution for quick surface and part repair. It instantly bonds to the surface with no welding, becoming a sacrificial layer that provides abrasion and erosion protection. Its cold bonding feature eliminates the need for a Hot Work Permit.

MeCaTeC is the ultimate protection layer for the demanding resurfacing requirements. Protect your assets with MeCaTeC!

Typical Applications include:

-

Ceramic tile and rubber lining replacement

-

Cyclones, chutes, bins and transfer points

-

Pipe elbows and slurry pipes

-

Slurry pumps

-

Screw conveyors

-

Bag house

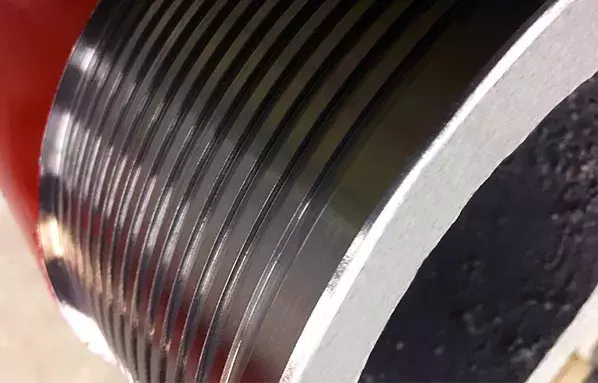

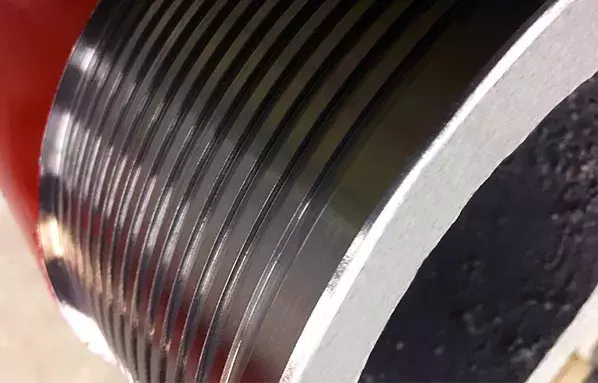

HIGH PERFORMANCE CRUSHER BACKING COMPOUNDS

Crusher backing compounds are a cost-effective way to protect crushing machines from friction, vibration and wear.

Our innovative line of crusher backing compounds is specifically designed to reinforce the liner, fill voids, reduce vibration and eliminate friction in rock crushing heavy machinery. It is easily applied between both gyratory and cone crusher liners and the crusher body part.

MeCaBack is an excellent choice of a crusher compound for mining, mineral processing and aggregate equipment including:

-

Crushing machines

-

Cone & stone crushers

-

Grinding mill liners

-

Backing plates

-

Lock bushings

PERFECT COMBINATION OF SAFETY, PERFORMANCE AND COST SAVINGS

-

Proprietary formula with Kevlar fiber interlocking technology

-

Engineered ceramic fillers to maximize wear performance

-

Optimized packaging for faster mixing during shutdown repairs

-

Excellent alternative to replace ceramic tiles and rubber linings

-

Rapid-cure formula ensures a quick return to service

-

Easy to apply with trowel, brush, MeCaSpray gun, or airless spray

-

On-site Technical Support with industry-leading expertise and application know-how

发现其他行业

CDP® XuperWave 4624 DXW is the ideal wearplate for the application where the right balance between price and service life is required