Aço

Choose a category

-

Imagem

Trituradoras de sínter

Trituradoras de sínter -

Imagem

VRM

VRM -

Imagem

Fume Ducts

Fume Ducts -

Imagem

Lingotamento

Lingotamento -

Imagem

Universal Applications

Universal Applications

Operação em ambientes extremos

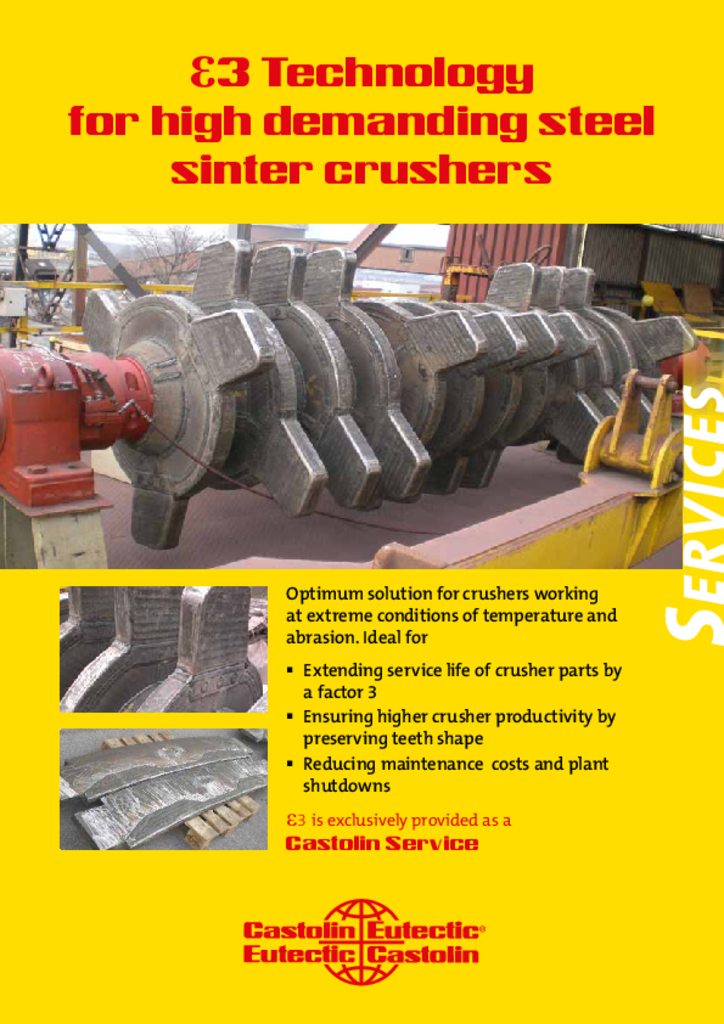

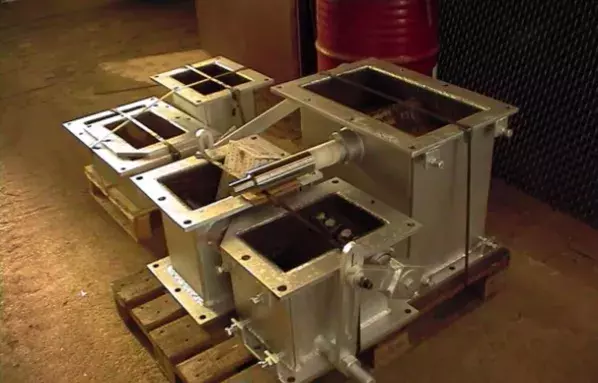

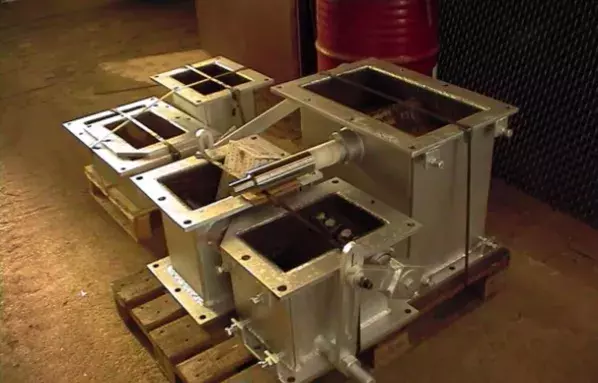

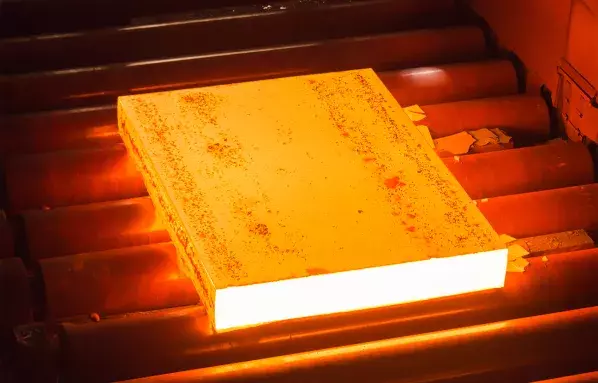

Em siderurgias, o equipamento que processa o sínter a temperaturas muito elevadas é exposto a condições de desgaste acentuadas. Particularmente, a trituradora de sínter que tem de garantir que o material de grandes dimensões deve estar protegido contra o desgaste, de forma a evitar manutenções dispendiosas e paragens frequentes na fábrica. Os gestores de manutenção concordam que as soluções standard disponíveis no mercado não são suficientes para as suas necessidades. Os rotores e barras de trituração devem ser regularmente substituídos por peças novas.

A resistência ao desgaste insuficiente das soluções standard deve-se, essencialmente, a três fatores:

• a temperatura elevada do sínter que reduz as características de revestimento,

• a natureza abrasiva do sínter que provoca desgaste nas peças,

• os impactos elevados que destroem os revestimentos frágeis.

e3 tem um desempenho, no mínimo, três vezes superior ao das soluções standard

A tecnologia e3 é uma solução legalmente protegida, especialmente desenvolvida para aumentar a produtividade de trituradoras de sínter e a sua vida útil. Esta solução foi criada após quatro anos de testes realizados em laboratório, assim como em condições de operação reais. Baseia-se numa liga exclusiva da Castolin Eutectic resistente ao desgaste a elevadas temperaturas, que oferece uma resistência extra, mesmo quando existe impacto e abrasão. A tecnologia e3 é especialmente adequada para proteger as peças fundamentais da trituradora de sínter, como discos rotores, dentes e barras de trituração. Os testes on-site demonstraram que a tecnologia e3 tem um desempenho, no mínimo, três vezes superior ao das soluções standard. Para além de aumentar a vida útil, a forma geométrica das peças é preservada, garantindo uma melhor eficiência da trituradora, comparativamente a soluções standard.

Os nossos engenheiros podem criar uma solução específica para as suas próprias necessidades

Para além de melhorar a vida útil das peças, a tecnologia e3 permite-lhe:

• reduzir a manutenção frequente da trituradora de sínter e as paragens da fábrica,

• obter uma produtividade trituradora superior preservando a forma dos dentes,

• reduzir os custos de compra de novas peças,

• evitar usar barras de trituração complexas arrefecidas com água.

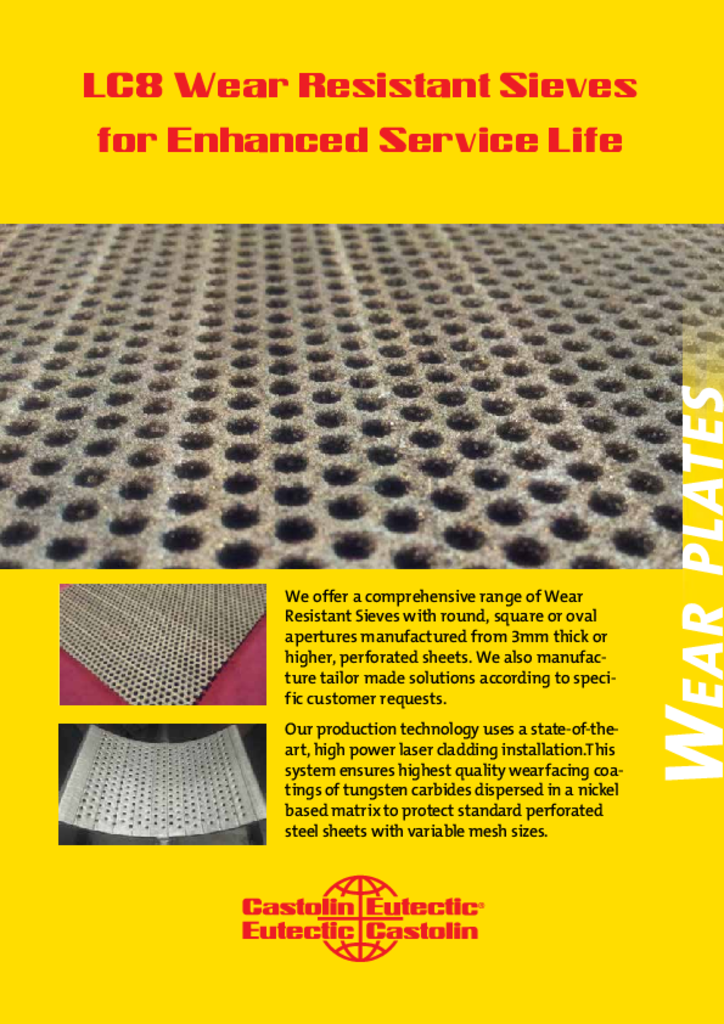

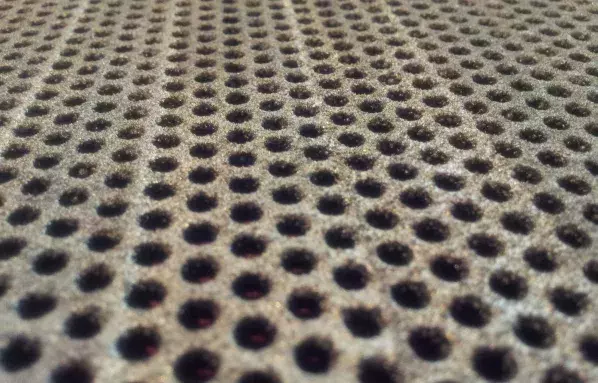

MADE BY LASER CLADDING

We offer a comprehensive range of wear-resistant sieves with round, square or oval apertures manufactured from 3 mm thick or higher, perforated sheets. We also manufacture tailor-made solutions according to specific customer requests. Our production technology uses a state-of-the-art, high power laser cladding installation. This system ensures highest quality wearfacing coatings of tungsten carbides dispersed in a nickel-based matrix to protect standard perforated steel sheets with variable mesh sizes.

Much better than standard steel

The ultra hard tungsten carbide phases which are homogeneously distributed within a self-fluxing, tough nickel-based alloy matrix, provide:

- Extreme wear resistance performance against abrasion and erosion up to 10 times higher than standard, monolithic heat-treated steel alternatives.

- Withstands operating service temperatures up to 400°C. For even higher service temperature requirements, a diverse range of special alloy systems may be proposed to meet specific customer needs.

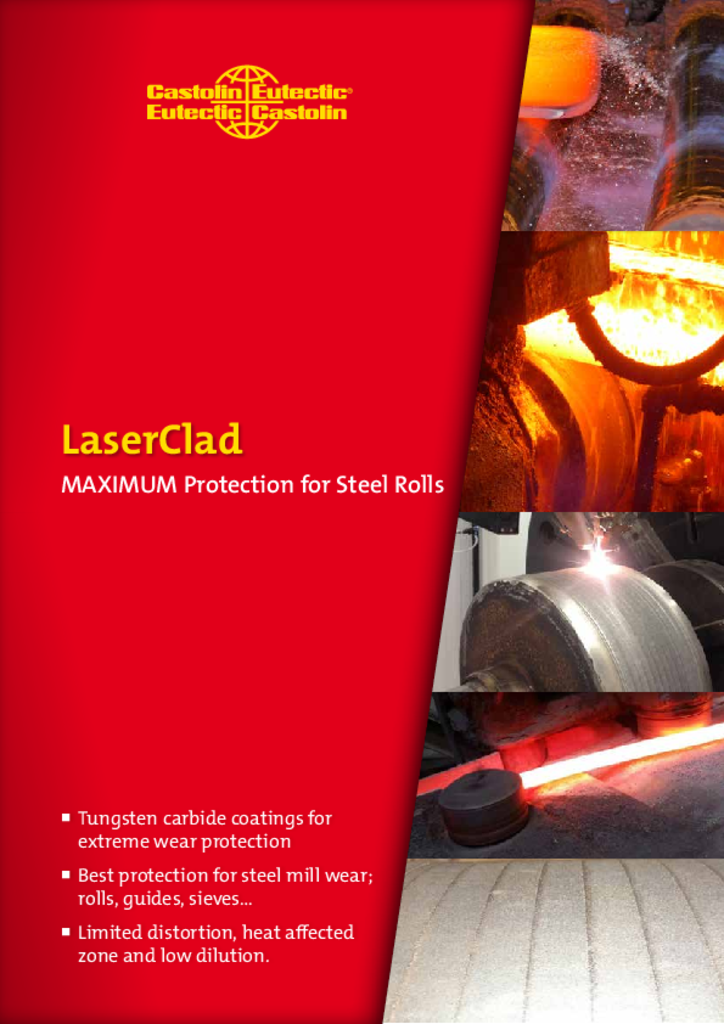

Modern Castolin Eutectic LaserClad technology uses a focused laser beam to ensure low heat input welding conditions, which translates into extremely effective, wear protective coatings on industrial parts.

Other Solutions for Sinter Plants

After mixing the raw materials in the sinter plants (fine iron ores, additives such as limestone and olivine, recycled iron-bearing materials from downstream operations, and coke breeze) we find a roller just underneath the charging system to constantly feed the sinter belt which is affected by abrasion. The lifetime of this feeding roller can be increased by our turnkey solutions.

Increase lifetime with CDP® wearplates

In most cases after the sinter discharge, crushing and hot screening, the sintered material proceeds to a separate cooler. This is typically a rotating structure, divided into circular sectors with tipping devices, in which the sinter is placed in a layer more than 1 m thick and cooled by fresh air.

When the sinter has completed the cooling cycle, each sector is emptied via the tipping device. The cooled sinter is transferred to screens that separate the pieces to be used in the blast furnace.

Both the charge and discharge of the cooler deteriorate the surfaces whose lifetime can be increased with our CDP® wearplates.

Cooling the steel is a critical factor

Along the whole sinter process, several metallurgical and chemical reactions take place which produce dust and gaseous emissions apart from the sinter itself. These gases contain particles such as heavy metals that will weaken the inner surface of air suction systems.

A complete high resistance conduction system including valves and transitions circular to square section can be manufactured with our CDP® wearplates.

Preventive wear protection of VRMs

Based upon hundreds of successful applications approved by our clients across the globe, Castolin Eutectic can provide optimized solutions with a wide range of products and technologies to combat wear in VRM (Vertical Roller Mill) and many more. Castolin Eutectic has a detailed understanding of the industries where this equipment is used, of every major wear problem and can provide industry tested application solutions.

From the extreme cold of Russia to the heat of Brazil and Mexico, we have a deep knowledge of application solutions for the wear problems in this industry. Innovative technologies and equipment help major industrial Groups to meet their objectives in terms of increased life time and plant performance.

Limited distorsion or shrinkage

The fume ducts in the Steel Plants are exposed to high erosion wear or corrosion. Moreover, their internal walls are subjected to the impact of erosive particles transported at high speed by ventilation gas at high temperatures. In some applications, ventilation gas is also corrosive.

Since decades, Castolin Eutectic has been the provider of choice for service, repair and preventive maintenance of heavy-duty and industrial process equipment.

In Iron & Steel, protecting your industrial process equipment, fume ducts, tubes and walls from future corrosion and erosion while also extending your tubes’ useful life, is vital to your operation’s bottom line.

Eutronic Arc is the highest productivity and lowest running cost thermal spraying process. Due to the low heat input, there is a very low dilution during the process with limited distortion or metallurgical modification of the substrate without any dilution.

This technology can be applied both in the workshop or in the field. It does not require the use of oxygen, kerosene or combustible gas which means more economic coatings.

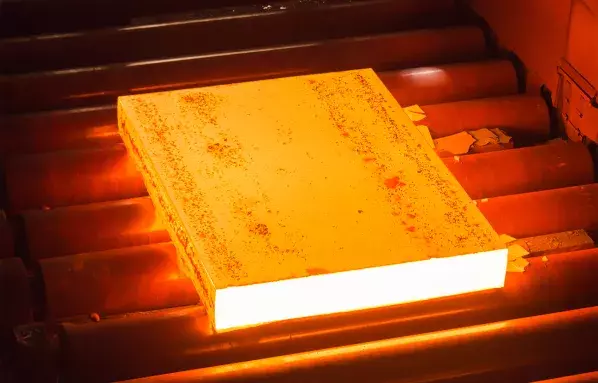

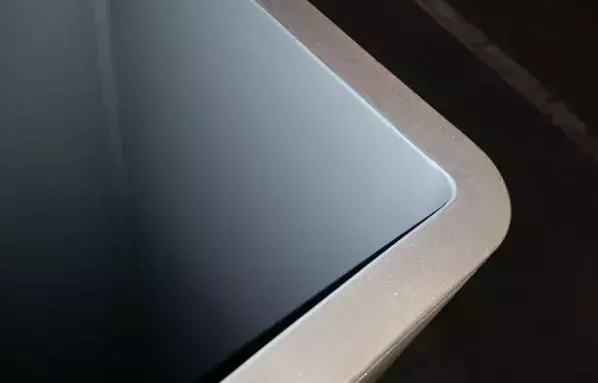

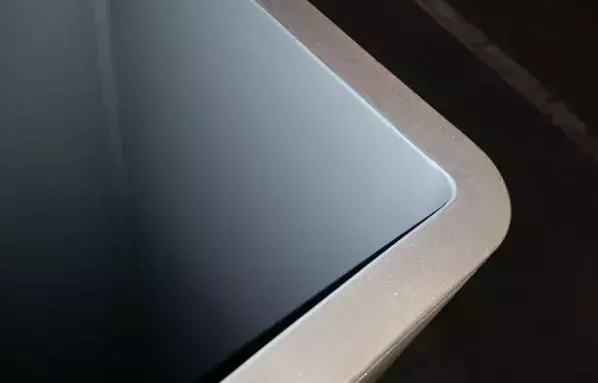

CastCoat da Monitor Coatings

O revestimento de compósitos duros CastCoat foi desenvolvido pela Monitor Coatings, a subsidiária da Castolin Eutectic no Reino Unido, para aplicações na indústria do aço, especialmente para revestimento de chapas de molde de cobre do fundidor, há mais de 20 anos. Os testes demonstram que o revestimento é mais robusto do que qualquer outro revestimento de chapa de molde de cobre disponível. Tem um coeficiente baixo de fricção, que ajuda a reduzir os alarmes de adesivo e o revestimento é inerte ao aço líquido e pós de fundição. O sistema de revestimento não tem efeito nos detetores de nível do molde ou nos agitadores eletromagnéticos. Também foi demonstrado que o revestimento tem um efeito insignificante nas taxas de transferência de calor.

Uma tecnologia mais amadurecida

Com anos de dados de campo sobre o revestimento, foram demonstradas melhorias significativas na vida útil da chapa de cobre: três a quatro vezes para fundidores de laje espessa e até seis vezes para chapas estreitas de fundidor de laje fina, juntamente com uma forma de produto melhorada. Na operação, o revestimento demonstrou ter capacidade de prolongar a vida do fundidor através de aumentos drásticos na resistência ao desgaste. A degradação progressiva do revestimento ocorre devido à fadiga térmica em posições de elevada pressão. Uma tecnologia mais amadurecida com uma base de clientes em todo o mundo, a CastCoat continua a fornecer aos utilizadores uma taxa de custos/tonelada mais reduzida.

Novo dispositivo HVOF compacto

Ao revestir as quatro faces do molde, a estabilidade dimensional é mantida ao longo da campanha, conduzindo a uma forma de produto e ao crescimento da cobertura sustentados e eficazes. A falta de desgaste considerável significa campanhas mais longas entre as trocas de moldes, alcançando uma disponibilidade do fundidor mais elevada. Adicionalmente, a proteção oferecida pelo revestimento proporciona uma vida prolongada da chapa de cobre, resultando em poupanças anuais de cobre e reduções significativas tanto nos custos de manutenção offline como online. Com o recente desenvolvimento de um dispositivo HVOF compacto, o CastCoat Composite Coating pode ser aplicado a moldes de tubo.

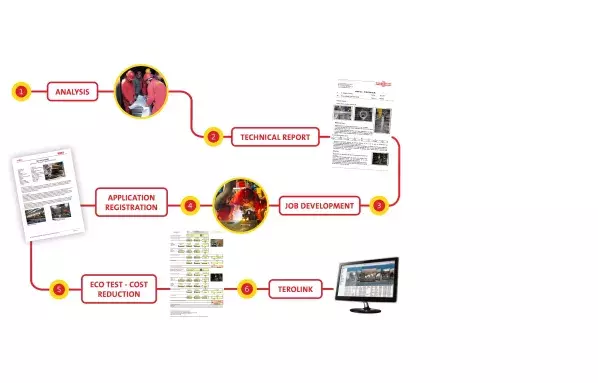

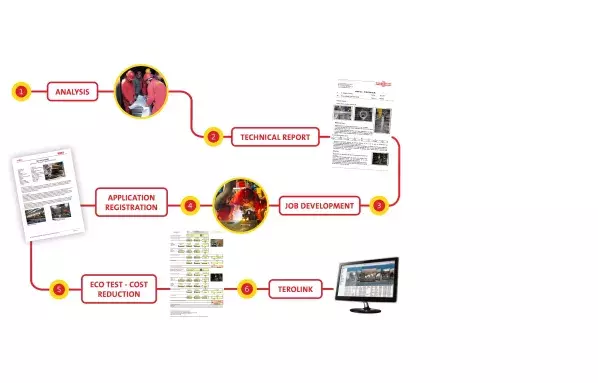

Our working method for cost savings

Since a very long time we are successfully applying a partnership program, focused on cost reductions. This smart Maintenance and Repair program can be summarized in six steps:

- Analysis: The first step to a good solution is a correct analysis.

- Technical Report: With the information provided, our Technical Department prepares a report.

- Job development: Once the client considers the repair to be feasible, Castolin Eutectic puts at your service all the Technical Department for the development of the procedure outlined above.

- App registration: Always subject to the customer’s approval, we first propose to register the job done in our confidential “FAR” database where the short application summary remains on hold until confirmation of service results.

- EcoTest: At the end of the service life of the part involved, we are ready to establish a detailed cost analysis to evaluate the practical direct savings achieved through mutual collaboration.

- Terolink: Finally we propose to submit the complete application as verified in our Terolink Database.

RAW MATERIAL PROCESSING & HANDLING

Iron ore, coal, limestone, fluxes and scrap are unloaded in the raw material area. They are classified, stored, crushed, grinded and handled for transport into the next production process. All these activities produce a combination of wear phenomena in the different machines and parts involved. Their service lifetime can be extended with different solutions, thanks to the cost reduction program from Castolin Eutectic.

The first step for a good solution is a correct analysis

After processing the respective raw materials, they pass through the blast furnace, electric arc furnace (EAF) or basic oxygen furnace (BOF) to get pig iron or Steel. The first step for a good solution is a correct analysis. To facilitate this, we have created an analysis document that can easily be completed in collaboration with our technical delegate. The document reflects the most important parameters to be considered to develop in-house solutions to your wear problems.

Repair Continous Casting Rollers according to OEM specifications

Continuous casting rolls are critical parts that are used for making the slabs, blooms or billets just after the tundish and moulds, at a very high temperature. The extreme working loads as well as the high temperature wear-out the rolls surface and, as a result, parts are damaged. Maintenance managers regularly have to decide to either scrap these expensive parts or try to repair them according to OEM specifications.

Rebuilding and repairing rolls for steel processing facilities

The semifinished products obtained after the continuous casting process have to be shaped before being comercialized. The first of these processes is hot rolling, from which sometimes final products are obtained and other times semifinished products intended for cold rolling or coating.

cooling the steel is a critical factor

In all rolling processes, cooling the steel is a critical factor. The speed at which the rolled product is cooled will affect the mechanical properties of the steel. Cooling speed is controlled normally by spraying water on the steel as it passes through and/or leaves the mill, although occasionally the rolled steel is air-cooled using large fans.

Rolls protected by laser cladding

Since the installation of laser cladding technology in the Castolin Eutectic Services Centers the wear protection of key tools such as rolls and guides has been raised to a new level. The utilization of 8kW High Power Direct Diode (HPDD) with automation leads to flexible production and superior quality. In addition, the powerful laser enables high deposition rates that can reduce the cost of the cladding operation. Compared to standard welding techniques, the dissolution of the carbides and the dilution of the cladding material are the lowest that can be achieved. As a result, the wear-resistance is maximized and the service-life is longer. The unique broad beam (up to 23mm wide) produces a flat coated surface that minimizes subsequent machining or grinding. Rolls can often be used as welded without further processing. The low heat input of the laser process means the lowest distortion of large and thin wall parts that can easily be cladded.

Rolls protected by spray & fuse

OEMs usually provide parts that have the surface coated with high wear resistant alloys such as Eutalloy® RW 12496. This coating is applied first by spraying a powder on the roller surface and then by fusing it just above the liquidus temperature. The process allows the coating to offer its best wear resistant properties and to perfectly bound on the steel substrate. On long and heavy parts, fusion is extremely difficult to be done correctly. Just after the spraying step, the part must be pre-heated homogeneously and kept in temperature while several torches fuse the powder all along the roll. In 2m long massive rolls, fusion may require up to 7 hours and any variation in temperature may result on an irregular surface quality. Since the part is exposed to very high temperature, deformation is also critical, especially on rolls made with thin wall tubes. Finally, if cooling is not well managed, thermal stresses can be so high that cracks may appear on the overlay. Our well-equipped service workshops as well as more than 10-years experience allow us to offer high quality overlays. Parts are coated by highly skilled operators that follow strict manufacturing methods. They regularly apply several powders according to what has been defined by OEMs.

Descubra outras indústrias