Health-Conscious and Cost-Effective: Castolin Eutectic’s new Iron-base coating powders

Thomas Eichhorn, Global Product Line Manager Coating at Castolin Eutectic, explains how a new generation of iron (Fe)-based metal powders called SafeCoat was designed to reduce health risks and costs associated with nickel alloys in plasma transferred arc (PTA) and laser cladding processes. Developed in the company's R&D lab in Dublin, these powders are ideal for advanced coating processes aimed at enhancing resistance against abrasive wear and pressure. Common applications include repairing cast-iron tools, rebuilding machine parts, and wearfacing for injection molding tools, with relevance in industries like automotive, plastic extrusion, and machine building.

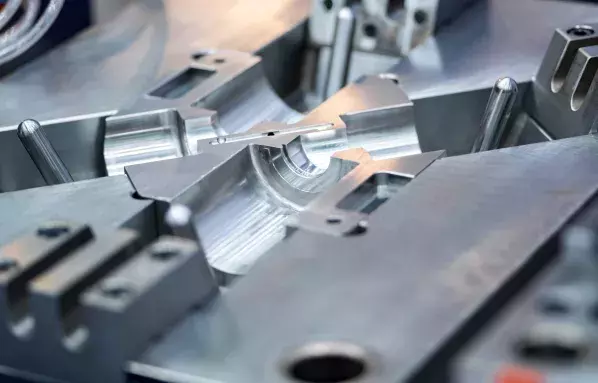

The PTA process creates a metallurgically bonded surface layer using a high-energy plasma arc and metal powder, resulting in improved wear resistance. Laser cladding complements this by using a laser beam to add coating powder to a molten pool on the workpiece surface, offering benefits like reduced substrate-coating mixing and minimal impact on the base material. These advancements in laser cladding technology allow for rapid, large-area applications at high speeds, making it suitable for various industrial applications, particularly where automated, low-maintenance, and profitable systems are required.

Advancing Health & Safety

There are a number of human health issues associated with nickel. Contact with the metal is known to have side effects such as allergies, cardiovascular, lung and kidney diseases.

In addition to human contact, nickel should be prevented from entering the atmosphere or water cycle. According to the German Water Hazard Class (WGK), nickel is ranked between 2: hazard to waters and 3: severe hazard to water. In contrast, iron is ranked 1: low hazard to waters or even zero.

For these reasons, using Fe-based powder rather than alloys containing nickel can promote a healthier working atmosphere. We have introduced the advantages of Fe-based metal powders in our new EuTroLoy series 16039D, 16045D, 16050D, and 16056D, available in sizes 45-125 and 53-150 µm, thereby broadening our offerings for PTA and laser cladding.

Eliminating Nickel – a big leap for affordability

PTA and laser cladding techniques have facilitated the introduction of Fe-based metal powders. This is due mainly to their higher process temperatures that have reduced the need for the self-fluxing properties of alloy powders with a significant nickel (Ni) content.

Nickel is a particularly costly alloying element, so using metal powder that does not include it offers an immediate cost-benefit. The pricing of nickel on the metal markets has tended to increase in recent years – up by 40% between 2021 and 2022. Furthermore, nickel pricing is also very volatile – in one day in 2022 it surged by 90%, end of 2023 values were down back again to 2021 levels. Elimination of nickel allows greater price stability for Fe-based powders.