New Product

June 5, 2014

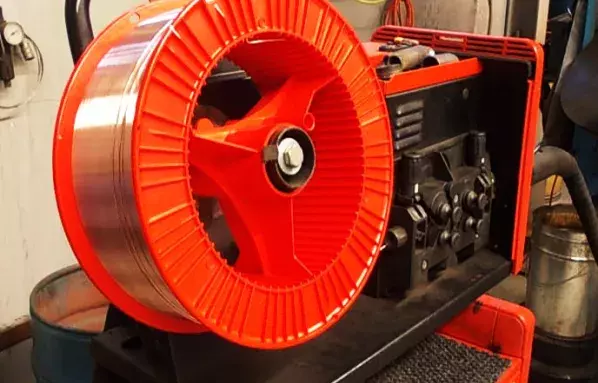

NEW EnDOtec Seamless SCW Range “Solid Cored Wires”

- Low heat input peripheral arc characteristics

- Reduced roller pressures & wire deformation / crushing risks

- Improved service life of torch contact tips

- Lower risk of lack of fusion defects

- Virtually zero moisture pick-up on wire in humid conditions

- Minimal solid residues accumulation in lining / torch

- Cleanest wire surface condition after drawing

EnDOtec DO*257: Joining and build up of modern low alloy, high tensile construction steels

Special Features:

- Concave weld profile in fillet joints.

- Elimination of bonding defects and sticking.

- Good resistance to impact at sub zero temperatures

- Welds with very low diffusible hydrogen content

EnDOtec DO*310: Ideal for rebuilding worn cast steel sections, medium carbon steel parts and buttering layers for wearfacing applications

Special Features:

- Good resistance to compression and plastic deformation.

- Multi-pass deposit capability.

- Dense, magnetic deposit.

- Readily machinable with cutting tools

EnDOtec DO*351: High alloy Cr-Si-C steel for wear protective coatings to resist impact, adhesion (metal-metal friction) and abrasion

Main Application:

- Forgeable deposit can be eat-treated or nitrided.

- Thermal shock resistance.

- Air hardening weld coatings

- Crack resistant wearfacing deposits

What's new in the Castolin Eutectic world?

Recent Posts