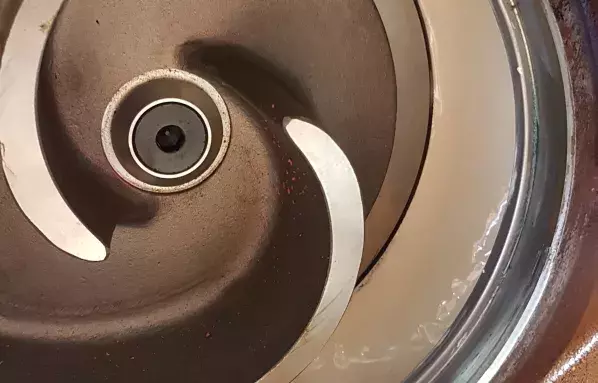

Pump lining techology reduces friction and absorbs energy of cavitation bubbles. Cavitation is a fluid mechanics phenomenon that is formed due to vapour cavities in a liquid, also known as “bubbles” that are a consequence of forces acting upon the fluid. It occurs when a fluid is subjected to rapid changes in pressure and forms bubbles where the pressure is low, when subjected to higher pressure these bubbles implode and can generate an intense shock wave causing major wear on the impeller and casings. This in turn, will alter the dynamics of the fluid flow, lowering the efficiency of the pump, which then drives up the energy costs. Cavitation is not solely a mechanical problem. Damage resulting from electro active fluids such as sea water can result in agressive galvanic attack from dissimilar metals in the pump as well as repair welds.