Did you know Castolin Eutectic launched an e-commerce site https://shop.castolin.com?

Deliveries are currently only to UK, Ireland, Germany, Austria and Romania. Here's a discount code for your first online purchase: RABATT10

Enjoy!

Choose a category

-

Image

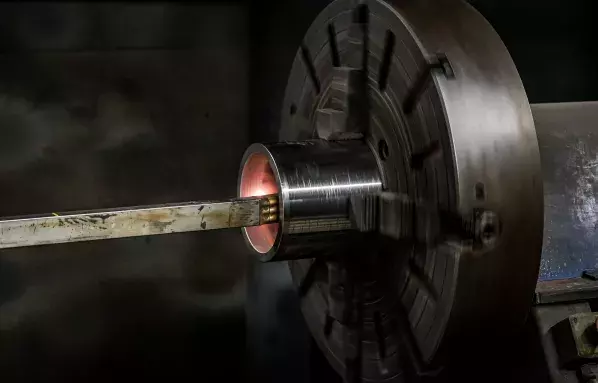

CDP® wearplates and CastoTubes®

CDP® wearplates and CastoTubes® -

Image

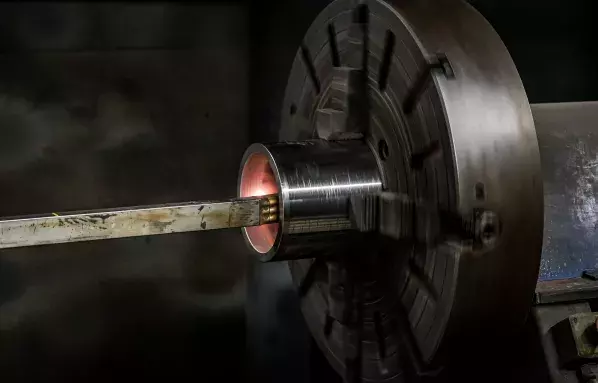

Laser cladding

Laser cladding -

Image

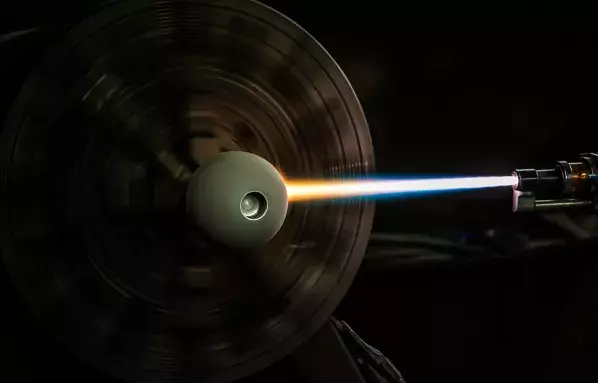

THERMAL SPRAY - HVOF

THERMAL SPRAY - HVOF -

Image

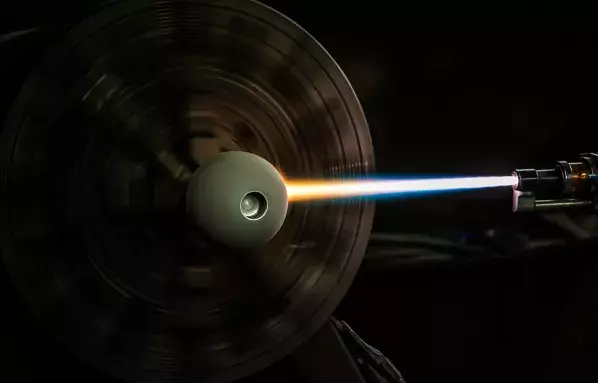

Welding and brazing

Welding and brazing -

Image

Selective Electroplating

Selective Electroplating

Increase plant availability

With more than 100 years experience in welding and wear protection, Castolin Eutectic is the manufacturer of the widest range of wearplates today on the market in terms of base materials, sizes, coating alloys, and welding processes adopted. From simple Chromium Carbide rich overlays, applied in open arc, to sophisticated NiCrBSi powders additioned with Tungsten Carbides and fused in a vacuum furnace or by means of Plasma Transferred Arc, we have developed a wide choice of products.

High value surface structure with excellent flatness

CDP® Powder Plates are produced by overlaying an easy-to-weld steel plate with a metal powder alloy fused in a furnace under protected atmosphere. The main advantage of these products is the 100% dilution-free overlay obtained, that ensures maximum protection even with just a few millimetres of deposit thickness. Lightweight and therefore easy to handle. Easily formed, and therefore also suitable to tight bending radius.

Custom cutting, elbows and joints available

They consist of easy-to-weld mild steel tubes which have been internally wearface-welded with TeroMatec 4666 alloy, thus maintaining the exceptional wear resistance of our well known 4666 CastoDur Diamond Plates®. Furthermore, by avoiding expensive forming operations of flat plates into tubes, seamless small diameter CastoTubes® offer many advantages:

- Highly cost-effective

- Absence of harmful linear weld joints

- Exceptional wear resistance

- Perfectly round cross section

- Spiral welding minimises distortion

- Lightweight for handling

- Highest quality metal powder

- Easy-to-join by welding or mechanical means

Cladding of advanced geometries and additive manufacturing

In Castolin Trio we have two 6kW high density diode lasers from Laserline Inc.

Lasers are supported by 6 axis and 3 axis CNC automatic welding machines, set-up for both powder and hot wire. CAM software packages are available for offline programming of advanced geometries and additive manufacturing of parts.

We have the ability to laser clad large parts up to 15m length, 12m continuous welding. The laser cladding process is supported by the Castolin Eutectic global R&D team with Ph.D. specialists within laser cladding. As manufacturers of powders, Castolin Eutectic can develop customised laser cladding powder/wire solutions tailored to your needs. In our Stavanger workshop, we also own an in-house lab for quality control of powders and new applications.

Tungsten Carbide content up to 60-70% for best wear resistance

- Low heat input causing lowest dilution: at 0.5-5% it is considerably lower than PTA and weld overlay.

- Low distortion: lower heat input means lower distortion of large parts, and less machining time.

- Faster: up to 7 Kg/Hour deposition rate for Tungsten Carbide containing alloys.

- High precision, High repeatability; constant and controlled quality.

- Best wear resistance due to advantages of welding Carbide powder blends with high Carbide content, up to 60-70%.

- The low dilution and fast cooling rate, gives unique microstructures with exceptional properties.

- Cladded thicknesses normally in range of 0.3-10mm depending on alloy. Some alloys offer no limitations.

Leader in HVOF coating technologies

Castolin Trio is a leader in HVOF coating technologies, offering both OD and ID HVOF coating. We have two JP-8000 HVOF systems, one cHVOF (ID) and two HVOF cells. One cell benefits from a traverse machine setup for easy handling and set up of parts for coating, the other cell is equipped with a robot for coating complex geometries and inside coating. Our thermal spray coating services are supported by our large capacity of precision grinding and CNC machining. We are also equipped with an in-house lab for quality control of powders and new applications.

Tremendous improvements in component performance

In contrast to welding, HVOF is a cold process where temperature of parts is kept below 150 °C, hence no thermal impact on the base material. HVOF is ideal for chrome plate replacement.

Typical coatings include high performance materials such as corrosion resistant metals, self-fluxing alloys and carbide blends. The various coatings can offer tremendous improvements in component performance such as wear, heat, oxidisation and corrosion resistance.

HVOF process is supported by the Castolin Eutectic global R&D team with Ph.D. specialists within HVOF. Castolin Eutectic is a manufacturer of powders for HVOF, and thus customized coating solutions can be developed.

HVOF characteristics:

- Temperature of part kept below 150 °C

- Adhesion strength ~ 69 Mpa

- <1% Porosity and low oxide

- Hardness values of up to 1400 Hv

- Surface roughness can be achieved down to 0,5 µm.

- International standards for testing are followed to ensure quality of coating

We offer welding services within TIG, MIG/MAG, MMA, PTA and oxyacetylene welding

Castolin Trio is an expert of welding services on a wide range of steels, including carbon steels, nickel steels, non-magnetic steels, duplex, stellite, bronze alloys etc. supported by qualified welding procedures and welding engineers/ IWE.

We offer welding services within TIG, MIG/MAG, MMA, PTA and oxyacetylene welding.

with tungsten carbide coatings

Castolin Trio is a specialist of brazing with tungsten carbide coatings, including tungsten carbide tiles and tungsten carbide rods.

We also perform Ag brazing of PDC and tungsten carbide inserts for drill bits and fishing tools on a regular basis.

Supporting processes

- Heat treatments services

- Machining

- Grinding

- Inspection (DPI, MT,PMI)

- Lab

- General mechanical workshop

Castolin Trio is a Norwegian representative of the SIFCO selective electroplating process

Selective brush electroplating is a portable plating method used to improve corrosion, erosion and wear properties, build up worn areas, salvage mismachined parts, as well as repair pitting and damages in base metal.

- Numerous pure metals and alloys are available using the selective plating process. Most often a combination of Copper build up and Nickel top layer.

- Copper or silver plating onto premium threaded connections for anti-galling purposes.

- Accurately controlled deposit thicknesses thus minimizes or eliminates post-machining operations.

- Can be performed at customer premises.

- Plated deposits have excellent adhesion.

- Cold process, typically 15-50 °C.

- Ideal for small ID repairs

- Require no or little disassembling of tools